Threaded Flanges Manufacturer, Supplier, and Exporter in India

Metalica Forging Inc. is a leading Threaded Flanges manufacturer in Mumbai, India. Our qualitative range of Threaded Flanges is exclusively designed for several piping applications of various industries Such as steel factories, chemical industries, petrochemical industry, fire protection systems, etc. We have types of Threaded Flanges that include Monel Threaded Flanges, Inconel Threaded Flanges, Carbon Steel Threaded Flanges, Copper Nickel Threaded Flanges, Stainless Steel Threaded Flanges, and more. Threaded Flanges are designed and developed in accordance with the IQS (International Quality Standards). We also offer customized Threaded Flanges as per the customer’s requirement.

ASTM A182 Threaded Flanges Manufacturers, ASME B16.5 Threaded Flanges Suppliers, and A234 WPHY 42/WPHY Threaded Flanges Stockists in India

Metalica Forging Inc is the world leader in Threaded Flanges manufacturer. We cater to the huge global demand of our clients who are spread across 5 continents and around 80 countries. Our Threaded Flanges are reputed and well known across the globe for their reliability and quality. We treat our clients as our partners by providing them with our products and services. Metalica Forging Inc manufactures Threaded Flanges of different shapes and sizes and with different specifications as per the customers’ requirements.

Threaded Flanges Specification, Grades, and Material

| Threaded Flanges | Specifications |

| Standards | ANSI, JIS, DIN, EN1092-1, UNI, BS4504, SABS1123, AS2129, GOST-12820 |

| Dimension | ANSI B 16.5 Threaded Flange, BS 1560. BS 10 Threaded Flange, IS 6392, B-2.1 NPT Threaded Flange, API Threaded Flange, DIN Threaded Flange, JIS. MSS SP 44 Threaded Flange |

| Material | ASTM A105 Threaded Flange, ASME A105 Threaded Flange ASTM A266 GR.1 Threaded Flange, GR.2 Threaded Flange, GR.3 Threaded Flange, GR.4 Threaded Flange ASTM A350 LF1 Threaded Flange, LF2 CL1/CL2 Threaded Flange, LF3 CL1/CL2 Threaded Flange ASTM A694 F42 Threaded Flange, F46 Threaded Flange, F48 Threaded Flange, F50 Threaded Flange, F52 Threaded Flange, F56 Threaded Flange, F60 Threaded Flange, F65 Threaded Flange, F70 Threaded Flange |

| Class | Threaded Flange 150#, Threaded Flange 300#, Threaded Flange 600#, Threaded Flange 900#, Threaded Flange 1500# & Threaded Flange 2500# |

| Size | 1/2” NB TO 24” NB. |

| Form | Threaded Flanges |

Grades |

|

| Stainless Steel | ASTM /ASME A/SA 213 / 249 / 269 / 312 / 358 CL. I to V – 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L . |

| Duplex Steel | ASTM/ASME A/SA 789, 790 – UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Carbon Steel | ASTM A106 Gr. A , B & C API 5L Gr. A / B, X42 ,X52 ,X60 ASTM A 53 Gr. A/B |

| Alloys Steel | ASTM /ASME A/SA 213 / 335 / 691 – P5,P9,P11,P12,P22,P91 |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

About Threaded Flanges

Threaded flanges are connecting with pipes without welding. It is the same to slip on flanges or socket weld flanges, fitted with a tapered thread (screw) inside the flange bore that is mounted on the pipe with corresponding external threads. In other cases, a seal weld additionally applied in conjunction with threaded pipe flanges.

Though threaded pipe flange is available in different dimensions, threaded fittings mostly use in small diameters pipeline. (Below 4 inches normally.)

It’s not compatible with a pipe system in thin wall thickness, since there’s no space for doing the threading.

Threaded Flange Types

There are two types of threaded flanges. One is to seal the 2 pipe ends with a certain sealing surface and a lens pad. This type of flanges is mostly used for ammonia production. But it has been useless recently, and the lens pad has been replaced by a metal ring. Threaded Flanges Manufacturer and Supplier are available all over the world.

Another type is the same as a normal flange, sealed with 2 flange sealing faces.

Facing Types

There are 2 facing types for threaded flange, ring joint flange, and raised face flange.

Raised Face Threaded Flange

When the gasket surface area is above the bolted line of the flange, the raised face flange is easily identified. It is compatible with a wide range of gaskets, from flat to semi-metallic and metallic types, either ring or full.

The main scope of a raised face flange design is to concentrate the pressure of the 2 mating flanges on a small surface and increase the strength of the seal.

The height of the raised face surface depends on the flange pressure level, for example, for pressure classes 150 and 300, the height is 1.6 mm or 1/12 inch, and for the 400 to 2500 level, the raised face height is about 6.4 mm, or 1/4 inch.

RTJ Threaded Flange

The Ring Joint Flange has a circular groove to accommodate the ring joint gasket, which can be used when metal to metal seals are required. Especially in conditions for high pressure and high temperature.

Referred Standard and Grades

ASTM A105: Standard forged carbon steel pipes components for environmental and high temperature / high-pressure systems.

ASTM A182: The standard for alloy and stainless threaded flanges. Common Stainless steel grades: F304, 304/, F316, F316L, alloy grades: F5, F9, F11, F22, F91.

Convenient Installation and Maintenance

The threaded flange is screwed to the threaded pipe by the thread, which is processed in the inner hole of the flange. So It does not need to be welded. Therefore, it became so convenient for installation and maintenance compared with other flange types, such as slip on flange, socket weld flange, etc.

Application in Special Circumstance

Threaded flanges are used where it is difficult to weld or cannot be welded, such as threaded flange used to protect the galvanized layer of pipe. In addition, It should not be utilized on pipes with repeated temperature fluctuations or above 260 ℃ and below -45℃ as well.

In ASME B31.3 standard it defines:

Where steel pipe is threaded and used for steam service above 250 psi or for water service above 100 psi with water temperatures above 220° F, the pipe shall be seamless and have a thickness at least equal to schedule 80 of ASME B36.10.

Measurement

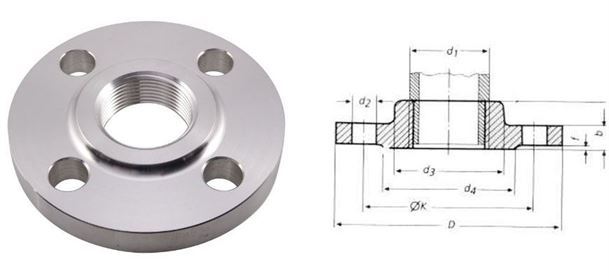

If threaded pipe flange can be measured accurately, the following data shall be required:

O: Outside Diameter of flange

C: Thickness of flange

R: Diameter of raised face

X: Hub Diameter at base

Y: Length through the hub

T: Minimum thread length

Q: Minimum diameter of the bolt circle

Threaded Flanges Applications and Uses

- Threaded Flanges used in Homes and buildings

- Threaded Flanges used in Transporting materials

- Threaded Flanges used in Automotive industry

- Threaded Flanges used in Sewerage systems, industrial water lines, and water mains.

- Threaded Flanges used in heating, ventilating, and air-conditioning equipment.

- Threaded Flanges used in Plumbing

- Threaded Flanges used in Food Processing Industry

- Threaded Flanges used in Paper & Pulp Industry

Metalic Forging INC is a Leading Supplier of Threaded Flanges in India

Metalic Forging INC is India’s most trusted Threaded Flanges Manufacturer in India. Our High-quality Threaded Flanges, sensible customer service, and in-house Threaded Flanges processing capabilities have made us one of the emerging and leading suppliers for Threaded Flanges in India. Metalic Forging INC is an ISO 9001:2009 certified company in Threaded Flanges manufacturer that has been in existence since 2004. Product dependability and performance have created Metalic Forging INC leading businessperson, manufacturers, and suppliers of Threaded Flanges in India. Metalica Forging is the Best Leading Threaded Flanges Manufacturer in India.

Class 150 Threaded Flanges Dimension Chart PDF

| FLANGE NPS |

Inside Diameter |

Outside Diameter |

Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 0.93″ | 3.50″ | 2.38″ | 1.38″ | .063″ | 1.19″ | .62″ | .38″ | .56″ | .62″ | 4 |

| 3/4″ | 1.14″ | 3.88″ | 2.75″ | 1.69″ | .063″ | 1.50″ | .62″ | .44″ | .56″ | .62″ | 4 |

| 1″ | 1.41″ | 4.25″ | 3.12″ | 2.00″ | .063″ | 1.94″ | .69″ | .50″ | .63″ | .62″ | 4 |

| 1-1/4″ | 1.75″ | 4.62″ | 3.50″ | 2.50″ | .063″ | 2.31″ | .81″ | .56″ | .75″ | .62″ | 4 |

| 1-1/2″ | 1.99″ | 5.00″ | 3.88″ | 2.88″ | .063″ | 2.56″ | .88″ | .62″ | .82″ | .62″ | 4 |

| 2″ | 2.50″ | 6.00″ | 4.75″ | 3.62″ | .063″ | 3.06″ | 1.00″ | .69″ | .94″ | .75″ | 4 |

| 2-1/2″ | 3.00″ | 7.00″ | 5.50″ | 4.12″ | .063″ | 3.56″ | 1.12″ | .82″ | 1.06″ | .75″ | 4 |

| 3″ | 3.63″ | 7.50″ | 6.00″ | 5.00″ | .063″ | 4.25″ | 1.19″ | .88″ | 1.13″ | .75″ | 4 |

| 3-1/2″ | 4.13″ | 8.50″ | 7.00″ | 5.50″ | .063″ | 4.81″ | 1.25″ | .88″ | 1.19″ | .75″ | 8 |

| 4″ | 4.63″ | 9.00″ | 7.50″ | 6.19″ | .063″ | 5.31″ | 1.31″ | .88″ | 1.25″ | .75″ | 8 |

| 5″ | 5.69″ | 10.00″ | 8.50″ | 7.31″ | .063″ | 6.44″ | 1.44″ | .88″ | 1.38″ | .88″ | 8 |

| 6″ | 6.75″ | 11.00″ | 9.50″ | 8.50″ | .063″ | 7.56″ | 1.56″ | .94″ | 1.50″ | .88″ | 8 |

| 8″ | 8.75″ | 13.50″ | 11.75″ | 10.62″ | .063″ | 9.69″ | 1.75″ | 1.06″ | 1.69″ | .88″ | 8 |

| 10″ | 10.88″ | 16.00″ | 14.25″ | 12.75″ | .063″ | 12.00″ | 1.94″ | 1.13″ | 1.88″ | 1.00″ | 12 |

| 12″ | 12.94″ | 19.00″ | 17.00″ | 15.00″ | .063″ | 14.38″ | 2.19″ | 1.19″ | 2.13″ | 1.00″ | 12 |

| 14″ | 14.19″ | 21.00″ | 18.75″ | 16.25″ | .063″ | 15.75″ | 2.25″ | 1.32″ | 2.19″ | 1.12″ | 12 |

| 16″ | 16.19″ | 23.50″ | 21.25″ | 18.50″ | .063″ | 18.00″ | 2.50″ | 1.38″ | 2.44″ | 1.12″ | 16 |

| 18″ | 18.19″ | 25.00″ | 22.75″ | 21.00″ | .063″ | 19.88″ | 2.69″ | 1.50″ | 2.63″ | 1.25″ | 16 |

| 20″ | 20.19″ | 27.50″ | 25.00″ | 23.00″ | .063″ | 22.00″ | 2.88″ | 1.63″ | 2.83″ | 1.25″ | 20 |

| 22″ | 22.19″ | 29.50″ | 27.25″ | 25.25″ | .063″ | 24.25″ | 3.13″ | 1.75″ | 3.07″ | 1.38″ | 20 |

| 24″ | 24.19″ | 32.00″ | 29.50″ | 27.25″ | .063″ | 26.12″ | 3.25″ | 1.82″ | 3.19″ | 1.38″ | 20 |

Class 300 Threaded Flanges Dimension and Sizes

| FLANGE NPS |

Inside Diameter |

Outside Diameter |

Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 0.93″ | 3.75″ | 2.62″ | 1.38″ | .063″ | 1.50″ | 0.88″ | 0.50″ | 0.82″ | 0.62″ | 4 |

| 3/4″ | 1.14″ | 4.62″ | 3.25″ | 1.69″ | .063″ | 1.88″ | 1.00″ | .056″ | 0.94″ | 0.75″ | 4 |

| 1″ | 1.41″ | 4.88″ | 3.50″ | 2.00″ | .063″ | 2.12″ | 1.06″ | 0.63″ | 1.00″ | 0.75″ | 4 |

| 1-1/4″ | 1.75″ | 5.25″ | 3.88″ | 2.50″ | .063″ | 2.50″ | 1.06″ | 0.69″ | 1.00″ | 0.75″ | 4 |

| 1-1/2″ | 1.99″ | 6.12″ | 4.50″ | 2.88″ | .063″ | 2.75″ | 1.19″ | 0.75″ | 1.13″ | 0.88″ | 4 |

| 2″ | 2.50″ | 6.50″ | 5.00″ | 3.62″ | .063″ | 3.31″ | 1.31″ | 0.82″ | 1.25″ | 0.75″ | 8 |

| 2-1/2″ | 3.00″ | 7.50″ | 5.88″ | 4.12″ | .063″ | 3.94″ | 1.50″ | 0.94″ | 1.44″ | 0.88″ | 8 |

| 3″ | 3.63″ | 8.25″ | 6.62″ | 5.00″ | .063″ | 4.62″ | 1.69″ | 1.06″ | 1.63″ | 0.88″ | 8 |

| 3-1/2″ | 4.13″ | 9.00″ | 7.25″ | 5.50″ | .063″ | 5.25″ | 1.75″ | 1.13″ | 1.69″ | 0.88″ | 8 |

| 4″ | 4.63″ | 10.00″ | 7.88″ | 6.19″ | .063″ | 5.75″ | 1.88″ | 1.19″ | 1.82″ | 0.88″ | 8 |

| 5″ | 5.69″ | 11.00″ | 9.25″ | 7.31″ | .063″ | 7.00″ | 2.00″ | 1.32″ | 1.94″ | 0.88″ | 8 |

| 6″ | 6.75″ | 12.50″ | 10.62″ | 8.50″ | .063″ | 8.12″ | 2.06″ | 1.38″ | 2.00″ | 0.88″ | 12 |

| 8″ | 8.75″ | 15.00″ | 13.00″ | 10.62″ | .063″ | 10.25″ | 2.44″ | 1.56″ | 2.38″ | 1.00″ | 12 |

| 10″ | 10.88″ | 17.50″ | 15.25″ | 12.75″ | .063″ | 12.62″ | 2.62″ | 1.82″ | 2.56″ | 1.12″ | 16 |

| 12″ | 12.94″ | 20.50″ | 17.75″ | 15.00″ | .063″ | 14.75″ | 2.88″ | 1.94″ | 2.82″ | 1.25″ | 16 |

| 14″ | 14.19″ | 23.00″ | 20.25″ | 16.25″ | .063″ | 16.75″ | 3.00″ | 2.06″ | 2.94″ | 1.25″ | 20 |

| 16″ | 16.19″ | 25.50″ | 22.50″ | 18.50″ | .063″ | 19.00″ | 3.25″ | 2.19″ | 3.19″ | 1.38″ | 20 |

| 18″ | 18.19″ | 28.00″ | 24.75″ | 21.00″ | .063″ | 21.00″ | 3.50″ | 2.32″ | 3.44″ | 1.38″ | 24 |

| 20″ | 20.19″ | 30.50″ | 27.00″ | 23.00″ | .063″ | 23.12″ | 3.75″ | 2.44″ | 3.69″ | 1.38″ | 24 |

| 22″ | 22.19″ | 33.00″ | 29.25″ | 25.25″ | .063″ | 25.25″ | 4.00″ | 2.57″ | 3.94″ | 1.63″ | 24 |

| 24″ | 24.19″ | 36.00″ | 32.00″ | 27.25″ | .063″ | 27.62″ | 4.19″ | 2.69″ | 4.13″ | 1.62″ | 24 |

Class 400 Threaded Flanges Dimension

| FLANGE NPS |

Inside Diameter |

Outside Diameter |

Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 0.93″ | 3.75″ | 2.62″ | 0.12″ | .250″ | 1.50″ | 1.13″ | 0.56″ | 0.88″ | 0.62″ | 4 |

| 3/4″ | 1.14″ | 4.62″ | 3.25″ | 0.12″ | .250″ | 1.88″ | 1.25″ | 0.62″ | 1.00″ | 0.75″ | 4 |

| 1″ | 1.41″ | 4.88″ | 3.50″ | 0.12″ | .250″ | 2.12″ | 1.31″ | 0.69″ | 1.06″ | 0.75″ | 4 |

| 1-1/4″ | 1.75″ | 5.25″ | 3.88″ | 0.19″ | .250″ | 2.50″ | 1.37″ | 0.81″ | 1.12″ | 0.75″ | 4 |

| 1-1/2″ | 1.99″ | 6.12″ | 4.50″ | 0.25″ | .250″ | 2.75″ | 1.50″ | 0.88″ | 1.25″ | 0.88″ | 4 |

| 2″ | 2.50″ | 6.50″ | 5.00″ | 0.31″ | .250″ | 3.31″ | 1.69″ | 1.00″ | 1.44″ | 0.75″ | 8 |

| 2-1/2″ | 3.00″ | 7.50″ | 5.88″ | 0.31″ | .250″ | 3.94″ | 1.87″ | 1.12″ | 1.62″ | 0.88″ | 8 |

| 3″ | 3.63″ | 8.25″ | 6.62″ | 0.38″ | .250″ | 4.62″ | 2.06″ | 1.25″ | 1.81″ | 0.88″ | 8 |

| 3-1/2″ | 4.13″ | 9.00″ | 7.25″ | 0.38″ | .250″ | 5.25″ | 2.19″ | 1.38″ | 1.94″ | 1.00″ | 8 |

| 4″ | 4.63″ | 10.00″ | 7.88″ | 0.44″ | .250″ | 5.75″ | 2.25″ | 1.38″ | 2.00″ | 1.00″ | 8 |

| 5″ | 5.69″ | 11.00″ | 9.25″ | 0.44″ | .250″ | 7.00″ | 2.37″ | 1.50″ | 2.12″ | 1.00″ | 8 |

| 6″ | 6.75″ | 12.50″ | 10.62″ | 0.50″ | .250″ | 8.12″ | 2.50″ | 1.62″ | 2.25″ | 1.00″ | 12 |

| 8″ | 8.75″ | 15.00″ | 13.00″ | 0.50″ | .250″ | 10.25″ | 2.94″ | 1.88″ | 2.69″ | 1.12″ | 12 |

| 10″ | 10.88″ | 17.50″ | 15.25″ | 0.50″ | .250″ | 12.62″ | 3.13″ | 2.12″ | 2.88″ | 1.25″ | 16 |

| 12″ | 12.94″ | 20.50″ | 17.75″ | 0.50″ | .250″ | 14.75″ | 3.37″ | 2.25″ | 3.12″ | 1.38″ | 16 |

| 14″ | 14.19″ | 23.00″ | 20.25″ | 0.50″ | .250″ | 16.75″ | 3.56″ | 2.38″ | 3.31″ | 1.38″ | 20 |

| 16″ | 16.19″ | 25.50″ | 22.50″ | 0.50″ | .250″ | 19.00″ | 3.94″ | 2.50″ | 3.69″ | 1.50″ | 20 |

| 18″ | 18.19″ | 28.00″ | 24.75″ | 0.50″ | .250″ | 21.00″ | 4.13″ | 2.62″ | 3.88″ | 1.50″ | 24 |

| 20″ | 20.19″ | 30.50″ | 27.00″ | 0.50″ | .250″ | 23.12″ | 4.25″ | 2.75″ | 4.00″ | 1.62″ | 24 |

| 22″ | 22.19″ | 33.00″ | 29.25″ | 0.50″ | .250″ | 25.25″ | 4.50″ | 2.88″ | 4.25″ | 1.75″ | 24 |

| 24″ | 24.19″ | 36.00″ | 32.00″ | 0.50″ | .250″ | 27.62″ | 4.75″ | 3.00″ | 4.50″ | 1.88″ | 24 |

Client Projects for Threaded Flange Supplier in India

Metalica Forging Inc. is one of the top-rated Threaded Flanges Manufacturer in India. Each month we tend to Supply Threaded Flanges products to around sixty countries and also to completely different customers. Over the last twenty years, we have delivered 3500+ containers of Threaded Flanges all over the world. Our company is a name that people trust in, our brand name implies fast delivery, affordable prices, and superior quality of Threaded Flanges. We have supplied Threaded Flanges in many cities in India. We also well-known for Threaded Flanges Manufacturer around the world.

| Product supplied | City |

| Threaded Flanges for Automobile Industry | Delhi, New Delhi |

| Threaded Flanges supply | Hyderabad, Telangana |

| Threaded Flanges supply for Water Supply System | Banglore, Karnataka |

| Threaded Flanges for Chemical industry | Surat, Gujarat |

Threaded Flanges Packaging & Delivery Details

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), Other

- Port of Dispatch: Mumbai OR KALAMBOLI India

- Packaging Details: Threaded Flanges are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra.

- Tax: 18% GST

Threaded Flanges Manufacturer in India

Threaded Flanges dependability and performance have created Metalica Forging INC leading Threaded Flanges Manufacturers, suppliers, dealers and exporters in India. Each month we tend to supply/export Threaded Flanges to Indian port around fifty-seven containers to completely different customers.

Due to giving a high quality of Threaded Flanges at lower prices with the simple services, we’ve our sales representatives at most of the vital cities of India that are:

| City we supply Threaded Flanges | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Threaded Flanges Exporter

Metalica Forging Inc exports Threaded Flanges in more than 50 countries. we have shipments going out monthly to different countries for our newly acquired customers. Our ready stock of Threaded Flanges helps us ship the Threaded Flange and meet the requirement and demands of our customers as fast as possible.

We additionally offer Threaded Flanges to alternative country

| Countries we supply and export Threaded Flanges worldwide: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | New Zealand |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

Saudi Arabia

Saudi Arabia Oman

Oman Kuwait

Kuwait Netherlands

Netherlands Iran

Iran Bahrain

Bahrain Qatar

Qatar UAE

UAE Africa

Africa New Zealand

New Zealand Nigeria

Nigeria Mexico

Mexico Canada

Canada Venezuela

Venezuela UK

UK USA

USA Malaysia

Malaysia Bangladesh

Bangladesh Turkey

Turkey Singapore

Singapore Sri Lanka

Sri Lanka Australia

Australia Brazil

Brazil Germany

Germany France

France Italy

Italy South Korea

South Korea Poland

Poland Belgium

Belgium Bangladesh

Bangladesh Oman

Oman Qatar

Qatar Saudi Arabia

Saudi Arabia Canada

Canada Malaysia

Malaysia UAE

UAE USA

USA Brazil

Brazil Nigeria

Nigeria Mexico

Mexico Iran

Iran France

France Kuwait

Kuwait Turkey

Turkey Bahrain

Bahrain Spain

Spain Algeria

Algeria Netherland

Netherland Australia

Australia Singapore

Singapore Zambia

Zambia Egypt

Egypt Venezuela

Venezuela Sudan

Sudan United Kingdom

United Kingdom Benin

Benin Vietnam

Vietnam Italy

Italy Poland

Poland