Forged Fitting End Connection Manufacturers, Supplier, and Exporter in India

Metalica Forging Inc. is a leading Forged Fitting End Connection manufacturers in Mumbai, India. Our qualitative range of Forged Fitting End Connection is exclusively designed for several piping applications of various industries Such as steel factories, chemical industries, petrochemical industry, fire protection systems, etc. We have types of Forged Fitting End Connection that include Monel Forged Fitting End Connection, Inconel Forged Fitting End Connection, Carbon Steel Forged Fitting End Connection, Copper Nickel Forged Fitting End Connection, Stainless Steel Forged Fitting End Connection, and more. Forged Fitting End connections are designed and developed in accordance with the IQS (International Quality Standards). We also offer customized Forged Fitting End Connection as per the customer’s requirement.

Forged Fitting End Connection Manufacturers, Forged Fitting End Connection Suppliers, and Forged Fitting End Connection Stockists in India

Metalica Forging Inc is the world leader in Forged Fitting End Connection manufacturers. We cater to the huge global demand of our clients who are spread across 5 continents and around 80 countries. Our Forged Fitting End Connection are reputed and well known across the globe for their reliability and quality. We treat our clients as our partners by providing them with our products and services. Metalica Forging Inc manufactures Forged Fitting End Connection of different shapes and sizes and with different specifications as per the customers’ requirements. We are also the top manufacturer of Forged Fitting Bushing.

Forged Fitting End Connection Specification, Grades, and Material

| Forged End Connection Fittings | Specifications | |||

|---|---|---|---|---|

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120,SCH140, SCH160, XXS | |||

| Size | 1/8″NB to 24″NB & 1/4″OD TO 24″OD AND 6.35mm to 254mm OD Thickness: 0.6mm to 20mm | |||

| Grades | ||||

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L | |||

| Super Duplex Steel | S32750 | |||

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. | |||

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 | |||

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. | |||

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 | |||

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI | |||

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L | |||

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G | |||

| Molybdenum | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM B387, Ferro Molybdenum | |||

| Cobalt | Cobalt HS-6, Cobalt HS-4, Cobalt HS-25, Sterlite Grade 1, Sterlite Grade 6, Sterlite Grade 12, Sterlite Grade 21 | |||

| Niobium | ASTM B394, R04200 R04210 | |||

| Nimonic | Nimonic75, Nimonic80, Nimonic85, Nimonic90, Nimonic263, etc | |||

| Tungsten | W1 WAl1, W61, etc, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten | |||

| Nichrome | Nichrome90, Nichrome80, Nichrome80A, Nichrome RW80, Nichrome75, etc | |||

| Magnesium | Magnesium AL017100, AL017140, AL017150, AL017160, AL017200, AL017210, AL017250, etc. | |||

| Tantalum | Tantalum – Grade 1. | |||

| Monel | Monel 400, Monel k500 | |||

| MU-METAL | MU-METAL | |||

| Zirconium | Zirconium 702, Zirconium 705, Zirconium 705, Zirconium-2, Zirconium-4 | |||

| Beryllium Copper | Alloy 25 UNSC17200 | |||

| Aluminium | 1050,1100, 2017, 7150, 7178, 7575, 2050, 7085, 2011 A92011, 2014A A92014, 2024 A92024, 2219, 5052 A95052, 5083 A95083, 5754, 6061 A96061 A86061, 6063, 6082 A96082, 7071 7020, 7050 A97050, 7075 A97075 A87075, 7175 | |||

| Copper Alloys | C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000 | |||

| Forged End Connection Fittings | Specifications | |||

|---|---|---|---|---|

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120,SCH140, SCH160, XXS | |||

| Size | 1/8″NB to 24″NB & 1/4″OD TO 24″OD AND 6.35mm to 254mm OD Thickness: 0.6mm to 20mm | |||

| Grades | ||||

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L | |||

| Super Duplex Steel | S32750 | |||

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. | |||

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 | |||

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. | |||

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 | |||

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI | |||

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L | |||

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G | |||

| Molybdenum | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM B387, Ferro Molybdenum | |||

| Cobalt | Cobalt HS-6, Cobalt HS-4, Cobalt HS-25, Sterlite Grade 1, Sterlite Grade 6, Sterlite Grade 12, Sterlite Grade 21 | |||

| Niobium | ASTM B394, R04200 R04210 | |||

| Nimonic | Nimonic75, Nimonic80, Nimonic85, Nimonic90, Nimonic263, etc | |||

| Tungsten | W1 WAl1, W61, etc, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten | |||

| Nichrome | Nichrome90, Nichrome80, Nichrome80A, Nichrome RW80, Nichrome75, etc | |||

| Magnesium | Magnesium AL017100, AL017140, AL017150, AL017160, AL017200, AL017210, AL017250, etc. | |||

| Tantalum | Tantalum – Grade 1. | |||

| Monel | Monel 400, Monel k500 | |||

| MU-METAL | MU-METAL | |||

| Zirconium | Zirconium 702, Zirconium 705, Zirconium 705, Zirconium-2, Zirconium-4 | |||

| Beryllium Copper | Alloy 25 UNSC17200 | |||

| Aluminium | 1050,1100, 2017, 7150, 7178, 7575, 2050, 7085, 2011 A92011, 2014A A92014, 2024 A92024, 2219, 5052 A95052, 5083 A95083, 5754, 6061 A96061 A86061, 6063, 6082 A96082, 7071 7020, 7050 A97050, 7075 A97075 A87075, 7175 | |||

| Copper Alloys | C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000 | |||

About Forged Fitting End Connection

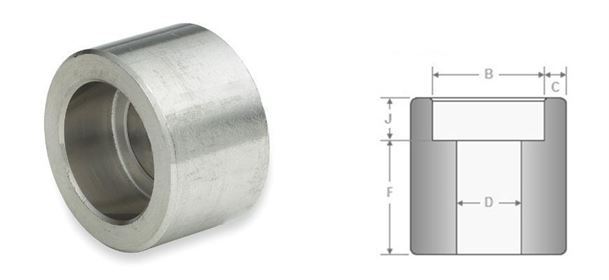

End Connection is one of the common Forged pipe fittings useful in the oil & gas industry. An End Connection provides a modification in material-flow direction. This adds pressure losses to the system due to impact, re-acceleration, and friction. As the product enters the inlet of the End Connection, it usually continues moving straight ahead to the primary impact zone. The product is then deflected at an angle toward the outlet of the End Connection. The deflection angle is intent by the End Connection design, the conveying velocity, the product’s characteristics, and specific load (also called the product-to-gas ratio). In several designs, the product will hit one or more secondary impact zones before exiting the End Connection. We are a specialist manufacturers of forged End Connection fittings in carbon steel, stainless steel, alloys steel, nickel alloys, duplex steel, Monel, beryllium copper, Inconel, copper steel, aluminum, titanium.

Forged Fitting End Connection Applications and Uses

- Forged Fitting End Connection used in Homes and buildings

- Forged Fitting End Connection used in Transporting materials

- Forged Fitting End Connection used in Automotive industry

- Forged Fitting End Connection used in Sewerage systems, industrial water lines, and water mains.

- Forged Fitting End Connection used in heating, ventilating, and air-conditioning equipment.

- Forged Fitting End Connection used in Plumbing

- Forged Fitting End Connection used in Food Processing Industry

- Forged Fitting End Connection used in Paper & Pulp Industry

Metalic Forging INC is a Leading Supplier of Forged Fitting End Connection in India

Metalic Forging INC is India’s most trusted Forged Fitting End Connection Suppliers in India. Our High-quality Forged Fitting End Connection, sensible customer service, and in-house Forged Fitting End Connection processing capabilities have made us one of the emerging and leading suppliers for Forged Fitting End Connection in India. Metalic Forging INC is an ISO 9001:2009 certified company that has been in existence since 2004. Product dependability and performance have created Metalic Forging INC leading businessperson, manufacturers, and suppliers of Forged Fitting End Connection in India.

Client Projects for Forged Fitting End Connection Supplier in India

Metalica Forging Inc. is one of the top-rated Forged Fitting End Connection Dealer in India. Each month we tend to Supply Forged Fitting End Connection products to around sixty countries and also to completely different customers. Over the last twenty years, we have delivered 3500+ containers of Forged Fitting End Connection all over the world. Our company is a name that people trust in, our brand name implies fast delivery, affordable prices, and superior quality of Forged Fitting End Connection. We have supplied Forged Fitting End Connection in many cities in India.

| Product supplied | City |

| Forged Fitting End Connection for Automobile Industry | Delhi, New Delhi |

| Forged Fitting End Connection supply | Hyderabad, Telangana |

| Forged Fitting End Connection supply for Water Supply System | Banglore, Karnataka |

| Forged Fitting End Connection for Chemical industry | Surat, Gujarat |

Forged Fitting End Connection Packaging & Delivery Details

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), Other

- Port of Dispatch: Mumbai OR KALAMBOLI India

- Packaging Details: Forged Fitting End Connection are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra.

- Tax: 18% GST

Forged Fitting End Connection Supplier in India

Forged Fitting End Connection dependability and performance have created Metalica Forging INC leading suppliers, dealers, manufactures, and exporters Forged Fitting End Connection in India. Each month we tend to supply/export Forged Fitting End Connection to Indian port around fifty-seven containers to completely different customers.

Due to giving a high quality of Forged Fitting End Connection at lower prices with the simple services, we’ve our sales representatives at most of the vital cities of India that are:

| City we supply Forged Fitting End Connection | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Forged Fitting End Connection Exporter

Metalica Forging Inc exports Forged Fitting End Connection in more than 50 countries. we have shipments going out monthly to different countries for our newly acquired customers. Our ready stock of Forged Fitting End Connection helps us ship the Forged Fitting End Connection and meet the requirement and demands of our customers as fast as possible.

We additionally offer Forged Fitting End Connection to alternative country

| Countries we supply and export Forged Fitting End Connection worldwide | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | New Zealand |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

Saudi Arabia

Saudi Arabia Oman

Oman Kuwait

Kuwait Netherlands

Netherlands Iran

Iran Bahrain

Bahrain Qatar

Qatar UAE

UAE Africa

Africa New Zealand

New Zealand Nigeria

Nigeria Mexico

Mexico Canada

Canada Venezuela

Venezuela UK

UK USA

USA Malaysia

Malaysia Bangladesh

Bangladesh Turkey

Turkey Singapore

Singapore Sri Lanka

Sri Lanka Australia

Australia Brazil

Brazil Germany

Germany France

France Italy

Italy South Korea

South Korea Poland

Poland Belgium

Belgium Bangladesh

Bangladesh Oman

Oman Qatar

Qatar Saudi Arabia

Saudi Arabia Canada

Canada Malaysia

Malaysia UAE

UAE USA

USA Brazil

Brazil Nigeria

Nigeria Mexico

Mexico Iran

Iran France

France Kuwait

Kuwait Turkey

Turkey Bahrain

Bahrain Spain

Spain Algeria

Algeria Netherland

Netherland Australia

Australia Singapore

Singapore Zambia

Zambia Egypt

Egypt Venezuela

Venezuela Sudan

Sudan United Kingdom

United Kingdom Benin

Benin Vietnam

Vietnam Italy

Italy Poland

Poland