Ring Joint Flanges Manufacturers, Supplier and Exporter in India

Metalica Forging Inc. is a leading Ring Joint Flanges manufacturers in Mumbai, India. Our qualitative range of Ring Joint Flanges is exclusively designed for several piping applications of various industries Such as steel factories, chemical industries, petrochemical industry, fire protection systems, etc. We have types of Ring Joint Flanges that include Monel Ring Joint Flanges, Inconel Ring Joint Flanges, Carbon Steel Ring Joint Flanges, Copper Nickel Ring Joint Flanges, Stainless Steel Ring Joint Flanges, and more. Ring Joint Flanges are designed and developed in accordance with the IQS (International Quality Standards). We also offer customized Ring Joint Flanges as per the customer’s requirement.

Ring Joint Flanges Manufacturers, Duplex Steel RTJ Flanges Supplier, Carbon Steel Ring Type Joint Flange Exporter in India

Metalica Forging Inc is the world leader in Ring Joint Flanges Manufacturers. We cater to the huge global demand of our clients who are spread across 5 continents and around 80 countries. Our Ring Joint Flanges are reputed and well known across the globe for their reliability and quality. We treat our clients as our partners by providing them with our products and services. Metalica Forging Inc manufactures Ring Joint Flanges of different shapes and sizes and with different specifications as per the customers’ requirements. We are also the top manufacturer of Spectacle Flanges in India.

Ring Joint Flanges Specification, Grades and Material

| Ring Joint Flanges | Specifications |

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Grades |

|

| Stainless Steel | ASTM /ASME A/SA 213 / 249 / 269 / 312 / 358 CL. I to V – 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L . |

| Duplex Steel | ASTM/ASME A/SA 789, 790 – UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Carbon Steel | ASTM A106 Gr. A , B & C API 5L Gr. A / B, X42 ,X52 ,X60 ASTM A 53 Gr. A/B |

| Alloys Steel | ASTM /ASME A/SA 213 / 335 / 691 – P5,P9,P11,P12,P22,P91 |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

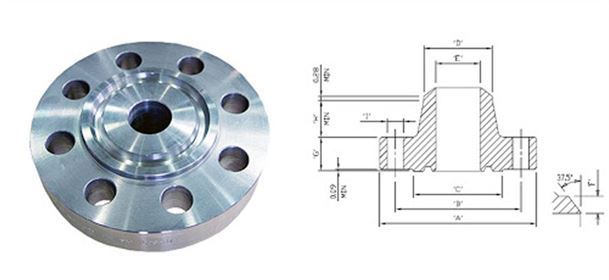

About Ring Joint Flanges

Ring Joint Flanges are generally utilized in high-temperature services above 800°F (427°C) and/or high pressure (Class 600 and bigger rating). They have grooves cut into their faces which are steel ring gaskets. The flanges seal once tightened bolts condenses the gasket between the flanges into the grooves, deforming (or Coining) the gasket to create intimate contact inside the grooves, making a metal to metal seal.

A Ring-Type Joint flange may have a raised face with a ring groove machined into it. This raised face does not function as any part of the sealing means. For RTJ flanges that seal with ring gaskets, the raised faces of the connected and tightened flanges could contact one another. During this case, the compressed gasket can not bear extra load beyond the vibration, bolt tension, and movement cannot more crush the gasket and lessen the connecting tension.

About Ring Type Joint Gaskets

Ring Type Joint gaskets are metallic sealing rings, suitable for high-temperature and high-pressure applications. They’re always applied to special, accompanying flanges which ensure good, reliable sealing with the proper selection of materials and profiles.

RTJ gaskets are created to seal by “initial line contact” or wedging action between the coupling flange and the gasket. The pressure is applied on the seal interface through bolt force, the “softer” metal of the gasket flows into the microfine structure of the harder flange materials, making a very tight and efficient seal.

The Style R ring is the most applied type that is manufactured in accordance with ASME B16.20 used with ASME B16.5 flanges, class 150 to class 2500. Style ‘R’ ring type joints are designed and manufactured in both octagonal and oval configurations.

The Oval has a lower sealing efficiency than the octagonal ring and would be the preferred gasket. Only the oval cross-section may be utilized in the old type round bottom groove. The newer flat bottom groove design can be accepted either the oval or the octagonal cross-section.

Style R ring type joints are created to seal pressure up to 6,250 psi in accordance with ASME B16.5 pressure ratings and up to 5,000 psi.

The RX type is more suitable for pressures up to 700 bar. This RTJ is capable of sealing itself. The outermost sealing surfaces make the first contact with the flanges. Higher system pressure causes higher surface pressure. RX Type is interchangeable with the standard R-models.

The BX type is more suitable for very high pressures up to 1500 bar. This BX type ring joint is not interchangeable with other types and is only best suited for API BX type flanges and grooves.

The sealing surfaces on the ring joint grooves must be smoothly finished to sixty-three Microinches and can be free of objectionable ridges, chatter marks, or tools. They seal by an “initial line contact” or a wedging action as the compressive forces are applied. The hardness of the ring is less than the hardness of the flanges.

Ring Joint Flanges Applications and Uses

- Ring Joint Flanges used in Homes and buildings

- Ring Joint Flanges used in Transporting materials

- Ring Joint Flanges used in Automotive industry

- Ring Joint Flanges used in Sewerage systems, industrial water lines, and water mains.

- Ring Joint Flanges used in heating, ventilating, and air-conditioning equipment.

- Ring Joint Flanges used in Plumbing

- Ring Joint Flanges used in Food Processing Industry

- Ring Joint Flanges used in Paper & Pulp Industry

Metalic Forging INC is a Leading Supplier of Ring Joint Flanges in India

Metalic Forging INC is India’s most trusted Ring Joint Flanges Suppliers in India. Our High-quality Ring Joint Flanges, sensible customer service, and in-house Ring Joint Flanges processing capabilities have made us one of the emerging and leading suppliers for Ring Joint Flanges in India. Metalic Forging INC is an ISO 9001:2009 certified company that has been in existence since 2004. Product dependability and performance have created Metalic Forging INC leading businessperson, manufacturers, and suppliers of Ring Joint Flanges in India.

ANSI B16.5 Class 150 Ring Joint Flanges Dimension

| Nominal Pipe Size | Pitch Diam. of Ring and Groove | Widthrong>of Ring | HEIGHT OF RING | Width at on Octagonal Rings | Widthroove | Depth of Groove | Diameter of Raised Face for Ring Joint or Lapped | Ring Number | Approximate Distance Between Flange of Ring Joints When Ring is Compressed | |

| OVal | Octagonal | |||||||||

| P | A | B | H | C | F | E(L*) | K(Min) | |||

| 1 | 47.6 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 63.5 | R15 | 4.1 |

| 1 1/4 | 57.2 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 73.2 | R17 | 4.1 |

| 1 1/2 | 65.1 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 82.6 | R19 | 4.1 |

| 2 | 82.6 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 101.6 | R22 | 4.1 |

| 2 1/2 | 101.6 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 120.7 | R25 | 4.1 |

| 3 | 114.3 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 133.4 | R29 | 4.1 |

| 3 1/2 | 131.8 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 153.9 | R33 | 4.1 |

| 4 | 149.2 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 171.5 | R36 | 4.1 |

| 5 | 171.5 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 193.5 | R40 | 4.1 |

| 6 | 193.7 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 218.9 | R43 | 4.1 |

| 8 | 247.7 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 273.1 | R48 | 4.1 |

| 10 | 304.8 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 330.2 | R52 | 4.1 |

| 12 | 381.0 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 406.4 | R56 | 4.1 |

| 14 | 396.9 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 425.5 | R59 | 3.0 |

| 16 | 454.0 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 482.6 | R64 | 3.0 |

| 18 | 517.5 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 546.1 | R68 | 3.0 |

| 20 | 558.8 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 596.9 | R72 | 3.0 |

| 24 | 673.1 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 711.2 | R76 | 3.0 |

Class 300 Ring Joint Flanges Dimension

| Nominal Pipe Size | Pitch Diam. of Ring and Groove | Widthrong>of Ring | HEIGHT OF RING | Width at on Octagonal Rings | Widthroove | Depth of Groove | Diameter of Raised Face for Ring Joint or Lapped | Ring Number | Approximate Distance Between Flange of Ring Joints When Ring is Compressed | |||

| OVal | Octagonal | |||||||||||

| P | A | B | H | C | F | E(L*) | K(Min) | Class 300 | Class 400 | Class 600 | ||

| 1/2 | 34.1 | 6.4 | 11.1 | 9.5 | 4.3 | 7.1 | 5.6 | 50.8 | R11 | 3.0 | – | 3.0 |

| 3/4 | 42.9 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 63.5 | R13 | 4.1 | – | 4.1 |

| 1 | 50.8 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 69.9 | R16 | 4.1 | – | 4.1 |

| 1 1/4 | 60.3 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 79.5 | R18 | 4.1 | – | 4.1 |

| 1 1/2 | 68.3 | 8.0 | 14.3 | 12.7 | 5.2 | 8.7 | 6.4 | 90.4 | R20 | 4.1 | – | 4.1 |

| 2 | 82.6 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 108.0 | R23 | 5.6 | – | 4.8 |

| 2 1/2 | 101.6 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 127.0 | R26 | 5.6 | – | 4.8 |

| 3 | 123.8 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 146.1 | R31 | 5.6 | – | 4.8 |

| 3 1/2 | 131.8 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 158.8 | R34 | 5.6 | – | 4.8 |

| 4 | 149.2 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 174.8 | R37 | 5.6 | 5.6 | 4.8 |

| 5 | 181.0 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 209.6 | R41 | 5.6 | 5.6 | 4.8 |

| 6 | 211.2 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 241.3 | R45 | 5.6 | 5.6 | 4.8 |

| 8 | 269.9 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 301.8 | R49 | 5.6 | 5.6 | 4.8 |

| 10 | 323.9 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 355.6 | R53 | 5.6 | 5.6 | 4.8 |

| 12 | 381.0 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 412.8 | R57 | 5.6 | 5.6 | 4.8 |

| 14 | 419.1 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 457.2 | R61 | 5.6 | 5.6 | 4.8 |

| 16 | 469.9 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 508.0 | R65 | 5.6 | 5.6 | 4.8 |

| 18 | 533.4 | 11.1 | 17.5 | 15.9 | 7.7 | 11.9 | 7.9 | 574.8 | R69 | 5.6 | 5.6 | 4.8 |

| 20 | 584.2 | 12.7 | 19.1 | 17.5 | 8.7 | 13.5 | 9.5 | 635.0 | R73 | 5.6 | 5.6 | 4.8 |

| 24 | 692.2 | 15.9 | 22.2 | 20.7 | 10.5 | 16.7 | 11.1 | 749.3 | R77 | 6.4 | 6.4 | 5.6 |

Client Projects for Ring Joint Flange Supplier in India

Metalica Forging Inc. is one of the top-rated Ring Joint Flanges Dealer in India. Each month we tend to Supply Ring Joint Flanges products to around sixty countries and also to completely different customers. Over the last twenty years, we have delivered 3500+ containers of Ring Joint Flanges all over the world. Our company is a name that people trust in, our brand name implies fast delivery, affordable prices, and superior quality of Ring Joint Flanges. We have supplied Ring Joint Flanges in many cities in India.

| Product supplied | City |

| Ring Joint Flanges for Automobile Industry | Delhi, New Delhi |

| Ring Joint Flanges supply | Hyderabad, Telangana |

| Ring Joint Flanges supply for Water Supply System | Banglore, Karnataka |

| Ring Joint Flanges for Chemical industry | Surat, Gujarat |

Ring Joint Flanges Packaging & Delivery Details

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), Other

- Port of Dispatch: Mumbai OR KALAMBOLI India

- Packaging Details: Ring Joint Flanges are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra.

- Tax: 18% GST

Ring Joint Flanges Supplier in India

Ring Joint Flanges dependability and performance have created Metalica Forging INC leading suppliers, dealers, manufactures, and exporters Ring Joint Flanges in India. Each month we tend to supply/export Ring Joint Flanges to Indian port around fifty-seven containers to completely different customers.

Due to giving a high quality of Ring Joint Flanges at lower prices with the simple services, we’ve our sales representatives at most of the vital cities of India that are:

| City we supply Ring Joint Flanges | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Ring Joint Flanges Exporter

Metalica Forging Inc exports Ring Joint Flanges in more than 50 countries. we have shipments going out monthly to different countries for our newly acquired customers. Our ready stock of Ring Joint Flanges helps us ship the Ring Joint Flange and meet the requirement and demands of our customers as fast as possible.

We additionally offer Ring Joint Flanges to alternative country

| Countries we supply and export Ring Joint Flanges worldwide | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | New Zealand |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

Saudi Arabia

Saudi Arabia Oman

Oman Kuwait

Kuwait Netherlands

Netherlands Iran

Iran Bahrain

Bahrain Qatar

Qatar UAE

UAE Africa

Africa New Zealand

New Zealand Nigeria

Nigeria Mexico

Mexico Canada

Canada Venezuela

Venezuela UK

UK USA

USA Malaysia

Malaysia Bangladesh

Bangladesh Turkey

Turkey Singapore

Singapore Sri Lanka

Sri Lanka Australia

Australia Brazil

Brazil Germany

Germany France

France Italy

Italy South Korea

South Korea Poland

Poland Belgium

Belgium Bangladesh

Bangladesh Oman

Oman Qatar

Qatar Saudi Arabia

Saudi Arabia Canada

Canada Malaysia

Malaysia UAE

UAE USA

USA Brazil

Brazil Nigeria

Nigeria Mexico

Mexico Iran

Iran France

France Kuwait

Kuwait Turkey

Turkey Bahrain

Bahrain Spain

Spain Algeria

Algeria Netherland

Netherland Australia

Australia Singapore

Singapore Zambia

Zambia Egypt

Egypt Venezuela

Venezuela Sudan

Sudan United Kingdom

United Kingdom Benin

Benin Vietnam

Vietnam Italy

Italy Poland

Poland